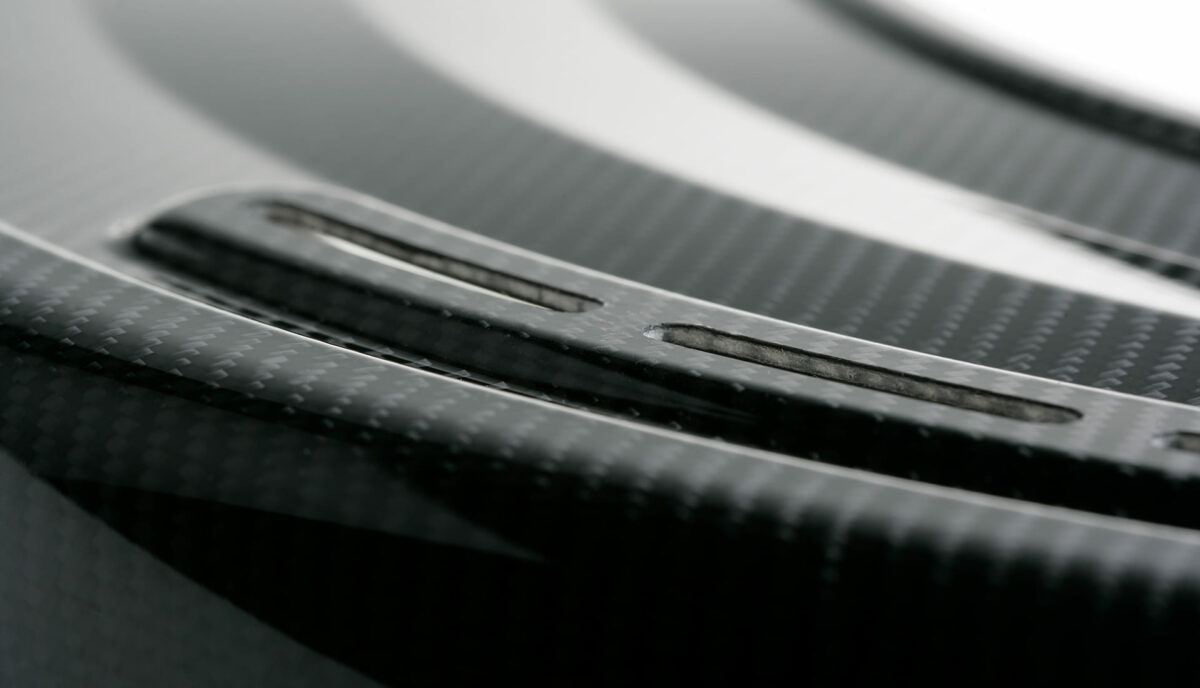

HexPly + TEXIPREG

HexPly® and TEXIPREG® prepreg systems

HexPly® and TEXIPREG® are fabrics and Non-crimp fabrics made of glass, carbon and aramid fibres impregnated with epoxy or phenolic resins. Different resin systems are available depending on the requirements of the finished component and selection of the suitable process. Important parameters when selecting the right resin system are, for example, thermal and mechanical properties of the cured material, flowability, curing temperature and curing time, tack, shelf life, etc. Prepregs must be stored deep-frozen and always in an airtight plastic bag. Before processing, the prepreg must be thawed in the closed bag at room temperature for at least 12 hours. Do not open before!

Shelf life at -18°C: 12–18 months, depending on the resin system.

Processable at 20°C: 7–60 days depending on the resin system.

HexPly® prepreg systems

Resin

Type

TG max (°C)

Curing range (°C)

Typical curing cycle

Properties and applications

M49

O

105

85–140

1 h at 120°C

Best optics. Approved by numerous OEMs for automotive interiors and exteriors.

M9.1

M9.6

S

135

75–160

8.5 h at 80°C

30' at 130°C

Variable curing conditions. For structures in wind energy, maritime, sports and industry.

M79

S/O

105

70–120

8 h at 70°C

1 h at 120°C

Low-temperature prepreg for large and thick structures in vacuum oven curing.

XF2-M79-FC

S

90

70–120

4 h at 80°C

Structural prepreg with integrated surface film based on M79. Directly paintable, non-porous surfaces after vacuum oven curing.

M34

F

100

65–120

16 h at 65°C

40' at 120°C

Self-adhesive on rigid foam and honeycomb. Self-extinguishing in accordance with DIN 5510 and NF F 16-101. For rail vehicles, electrical and electronic applications.

M901

S

195

130–170

10' at 130°C

+ 3 h at 150°C

Structural prepreg with high heat resistance. Very fast precuring: Can be demoulded and processed after 10 min. @ 130°C.

M81

S

200

135–180

3 h at 135°C

2 h at 180°C

Impact-modified, very high Tg-wet. For thermally and dynamically highly stressed components.

8552

S

200

180

1 h at 110°C

+ 2 h at 180°C

High strength, high Tg-wet. Impact-resistant modified, for structural components in aviation and racing.

TEXIPREG® prepreg systems

Resin

Type

TG max (°C)

Curing range (°C)

Typical curing cycle

Properties and applications

ET445 (EP)

O/S

135

80–150

30' at 125°C

Excellent cosmetic properties, high gloss level. For carbon optics in automotive engineering.

ET430 (EP)

O

120

135

2 h at 135°C

Best cosmetic properties. Clear film, high gloss level. For carbon optics without "white wash".

ER450 (EP)

S

210

80–180

90' at 135°C

+ 2 h at 200°C

Impact-modified, for structural components subject to high stress loads up to 180°C. Very flexible curing.

ER563 (EP)

S

238

180

2 h at 180°C

+ 2 h at 200°C

Impact-modified, for structural components subject to high thermal loads up to >200°C.

EY440 (EP)

S

147

120–150

30' at 120°C

3' at 150°C

Structural prepreg with short cycle times for medium-sized and large product runs. For automotive, sporting goods and industrial parts.

EF455 (EP)

F

180

120–135

2 h at 135°C

Flame retardant and self-extinguishing according to FAR 25.853 App.F-Tl.1; UL94-V0

ES161 (EP)

S

190

45–80

14 h at 45°C

7 h at 55°C

Low-temperature prepreg for mould making. Non-porous surfaces; very low shrinkage.

FF563 (PH)

F

170

120–160

75' at 135°C

Phenolic resin prepreg with the highest flame retardant properties; e.g. FAR.25.853. For automobile and aircraft interiors.

O = suitable for carbon optics. S = suitable for structural components. F = suitable for fire protection applications.

HexPly® are products from Hexcel.

TEXIPREG® are products of CIT.

Resin

Tack

Colour

Weight (g/m²)

Curing process

Properties and applications

XF3

Medium

grey

300

Autoclave: recommended

Press: possible

For automotive exterior applications. Excellent paint adhesion: curing between 120°C and 180°C possible. Can be combined with HexPly prepregs M10, M47 and M49.

Mould making prepreg HexTool®

HexTool® is a millable tooling prepreg for toolmaking and meets the highest requirements for dimensional accuracy and durability. HexTool moulds are used for manufacture of prepreg components in the aerospace, automotive and other industrial sectors. HexTool® has a similarly low thermal expansion and is almost six times lighter than the high-quality tool steel INVAR. When making the mould, a rough contour model is sufficient. After curing in an autoclave, the mould cavity is milled to its final dimensions using CNC machining. Unlike conventional composite moulds, HexTool® moulds can be repaired or modified at any time. HexTool® consists of carbon fibre and BMI resin (HexTool M61) or epoxy resin (HexTool M81) and is vacuum-tight, pressure-resistant and temperature-stable when cured.

Product designation

Weight (g/m²)

Curing temp. (°C)

Pressure (bar)

Thickness (mm)

TG max. (°C)

HexTool M81/2000

2.000

120–180

7

1.28

220

HexTool M61/2000

2.000

190

7

1.25

275